Our January 2023 extension column is by MNSG Aquaculture Extension Associate Kieran Smith and is an update on Minnesota Sea Grant’s Egg-to-Market Yellow Perch Project.

You may recall that one of the outcomes of this project is to create a detailed how-to manual for small- to medium-scale Yellow Perch (YEP) producers. Over the course of two years, the YEP project team will grow two batches of fish from embryo to harvest size. The team will compare fish growth in two separate systems:

- A recirculating aquaculture system (RAS). In a RAS, the water the fish live in is recycled continuously and requires very little water exchange. For example, our RAS tanks only require around 33 gallons of new water per day.

- A flow-through system. In the flow-through system water will travel only one time through the tanks. This system uses more than 15,000 gallons of water per day.

Figure 1. A video of the flow-through system with more than 400 Yellow Perch in each tank. The water flows from temperature-controlled head (or holding) tanks into the flow-through system where it passes through just once before exiting into a floor drain. Video credit: Kieran Smith.

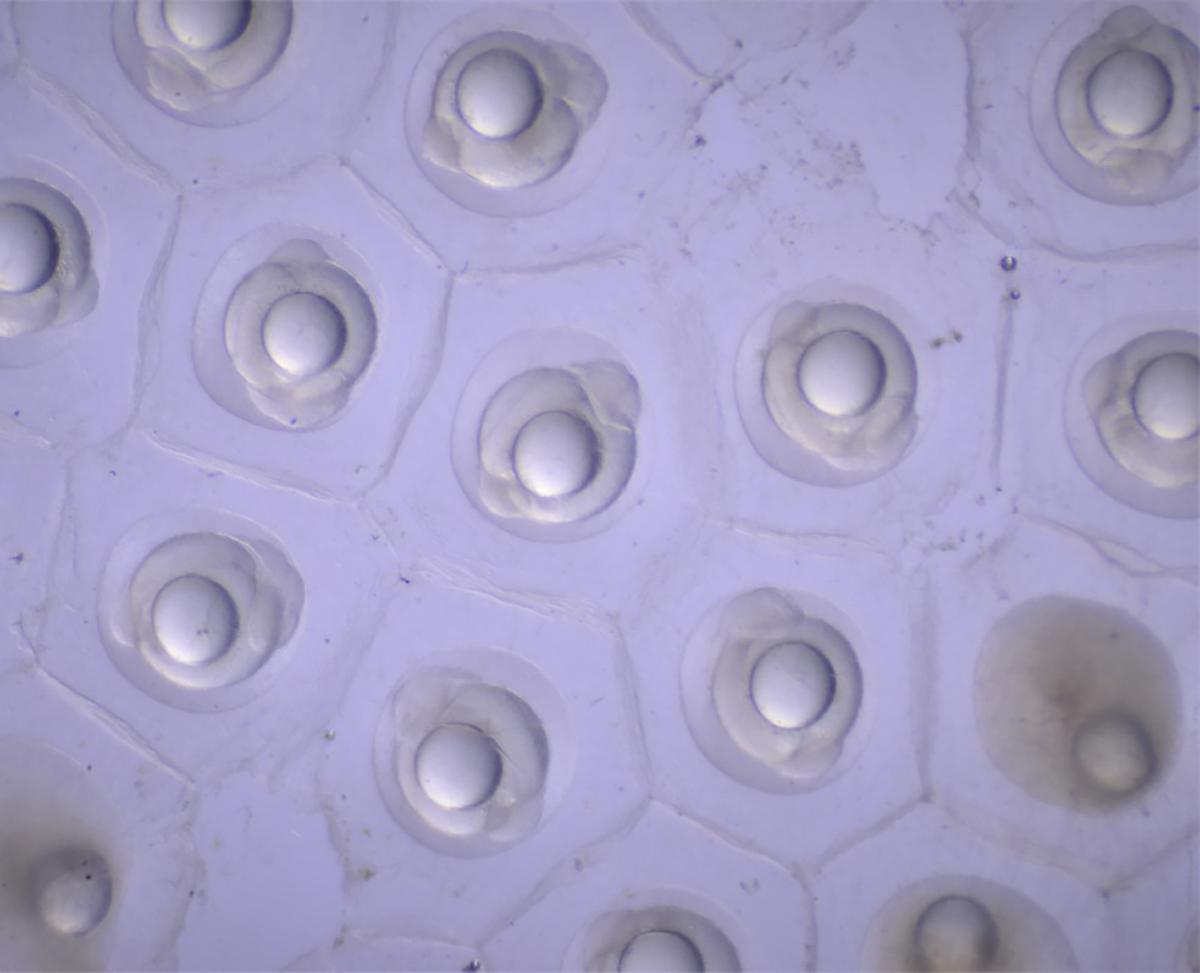

The first batch of Yellow Perch embryos arrived April 19, 2022 at the project team’s lab space in the Minnesota Aquatic Invasive Species Research Center (MAISRC) Containment Lab on the University of Minnesota St. Paul campus. Image credit: Kieran Smith.

After 10 days of incubation, the embryos hatched into thousands of skinny little larvae around one-fourth of an inch in length. While the larvae grew into juvenile fish, the project team plumbed the flow-through and constructed the recirculating aquaculture systems.

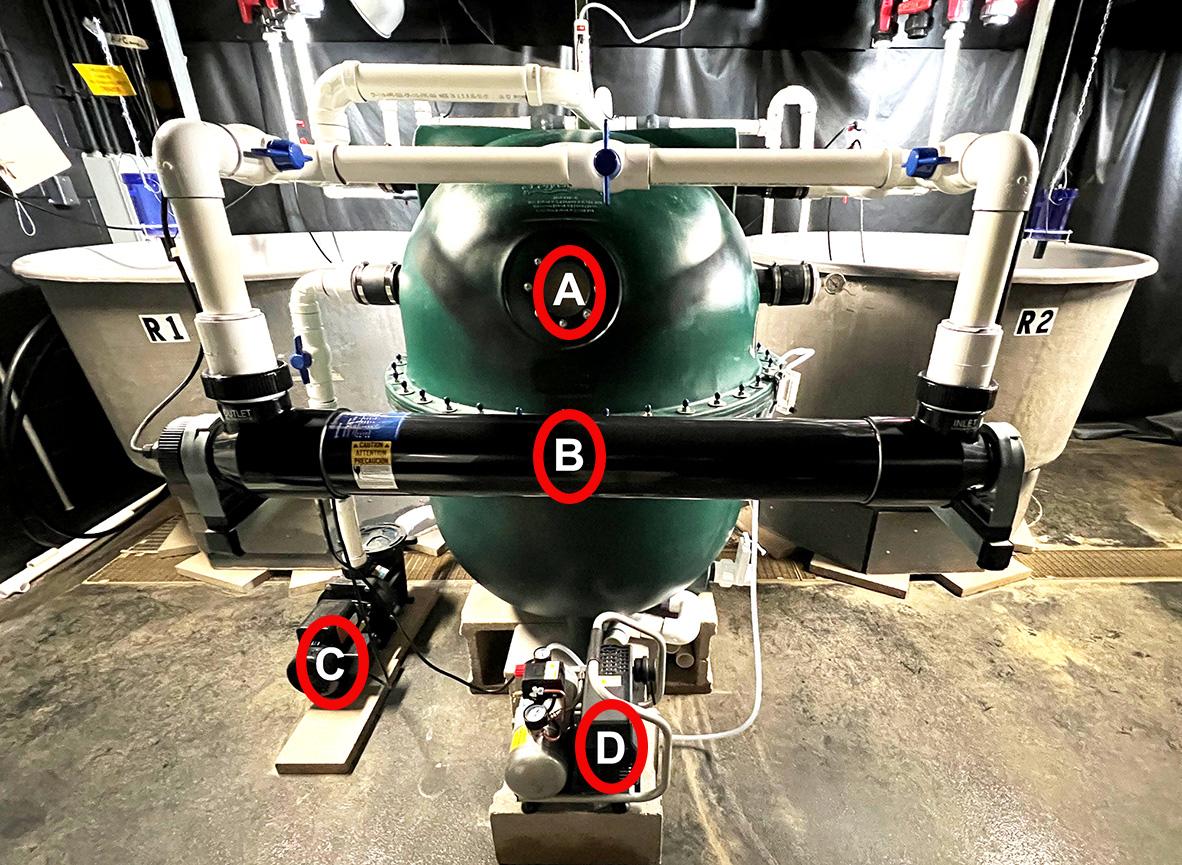

If you’re into DIY plumbing, you might appreciate this next part:

- First, we plumbed together the Polygeyser biofilter, a UV sterilizer, and a 90-gallon-per-minute water pump.

- Second, we connected them to a sump tank and two 250-gallon circular tanks.

- Third, we plumbed two more 250-gallon tanks for the flow-through system, which is separate from the recirculating aquaculture system (RAS) tanks.

- Fourth, we transferred 1,752 fish into the four, 250-gallon circular tanks (438 per tank) that now form our RAS and flow-through systems so they could continue to grow.

Figure 2. Photo of installed recirculating aquaculture system (RAS) with major components labeled. Image credit: Kieran Smith.

- (A) The Polygeyser biofilter is filled with thousands of small plastic beads that provide substrate (i.e., surface area) for the nitrifying bacteria to colonize and convert ammonia (from fish poop) into nitrite (which is toxic to fish) and then into nitrate (nontoxic to fish).

- (B) The large black plastic tube houses a long UV bulb which acts as a sterilizer and clarifier to remove bad bacteria and algae in the RAS water.

- (C) The air compressor fills a chamber in the bottom of the biofilter with air, which displaces ~6 cubic feet of water and when full, backwashes the system to remove excess sludge (uneaten food and waste) from the system.

- (D) The 90-gallon-per-minute pump circulates water through the system.

For this project’s RAS we purchased a Polygeyser biofilter built by Aquaculture Systems Technologies (AST). Nitrifying bacteria is a key component of this biofiltration system, which uses and provides the fish with a steady supply of clean freshwater and a healthy environment for growth. The biofiltration system is used to concentrate solid waste products (i.e., fish poop) into a sludge for removal and convert harmful fish by products such as ammonia into nitrite and then convert the nitrite into less harmful nitrate in a process called nitrification.

Figure 3. Video of the recirculating aquaculture system (RAS) with more than 400 fish per tank. The water flowing in this system is recirculated repeatedly with less than 5% exchanged each day. You can see the UV sterilizer at work as we walk from one tank to the other. Video credit: Kieran Smith.

Figure 4. Underwater video of ~260-day-old Yellow Perch in the flow-through system. The air stone in the background helps to circulate water and maintain adequate levels of dissolved oxygen within the tank. You may see some excess pellet feed rolling around the bottom of the tank. These fish feed only from within the water column, they are not bottom feeders. If the feed hits the bottom of the tank, it remains uneaten and must be removed at the end of the day. As you can see, these Yellow Perch are pretty curious! Video credit: Kieran Smith.

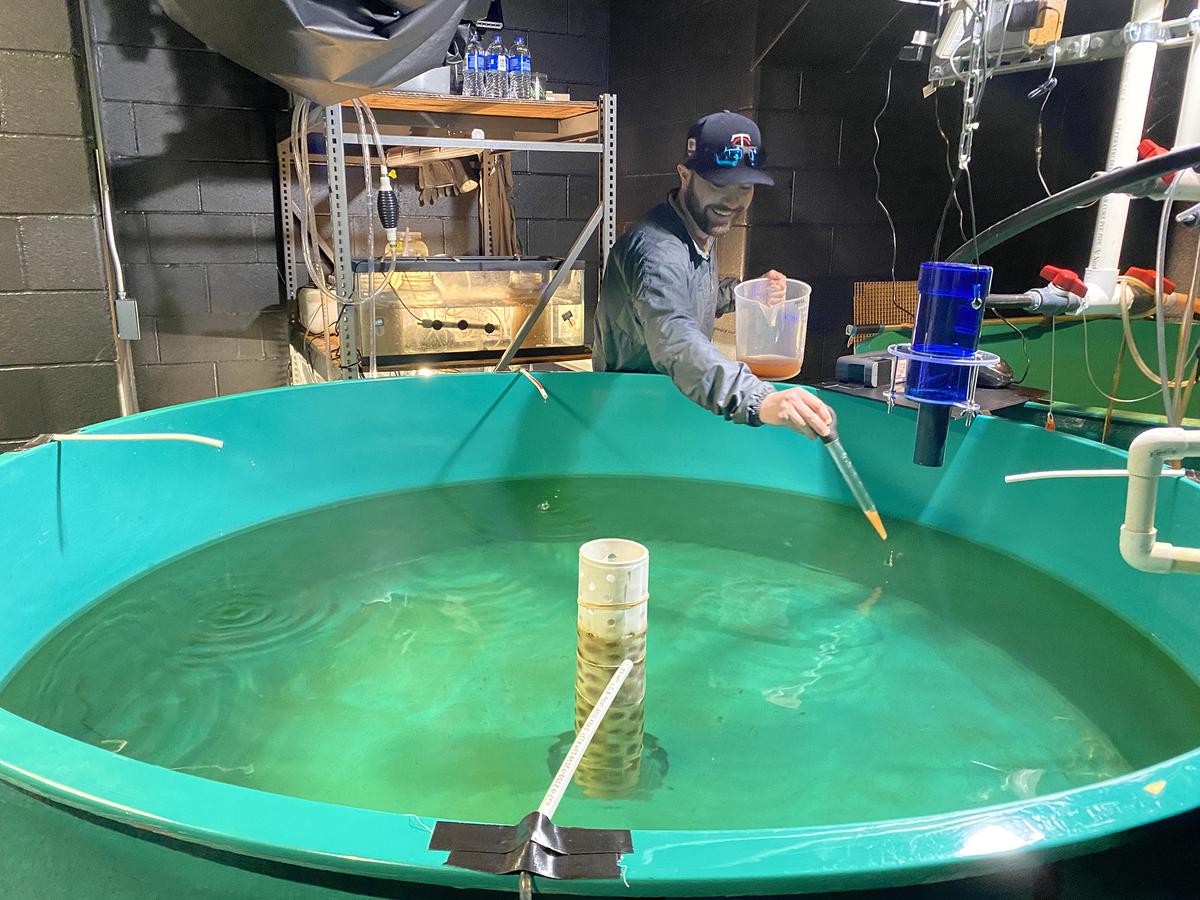

Every day, the project team checks the water quality, which includes checking temperature, dissolved oxygen, ammonia, nitrite, nitrate and assesses fish behavior and health in both the flow-through and RAS systems. We also feed the Yellow Perch a high-quality pelleted diet eight times a day using vibratory feeders purchased from Pentair Aquatic Ecosystems.

The amount of feed is increased as the fish grow and every 30 days our team weighs and measures around 10% of the fish in each tank to track their progress. Just 12 months after they hatch into larvae, the adult fish will be ready for harvest, processing, and eating! Fish tacos anyone?

Keep an eye out for future updates on this project and more aquaculture related news from Minnesota Sea Grant!